Yet another precise industry that may leverage CAPA may be the maritime industry. Using the ISPS code and the proper steps and system, the maritime industry can reduce occurrences that may threaten its stability.

Making use of a corrective action is often a simple system. Every time a worker or inspector reports a problem, step one of implementing a corrective action is to ascertain the basis reason for the issue and determine an answer. Afterward, the group will have to monitor the situation in order that the action was efficient.

Modifications shall contain overview and revision of interim Handle actions to reduce chance, the place relevant.

Establishing a whole abide by-up to make sure the correction is helpful, and the probability of reoccurrence in the defect are prevented.

Considering that this problem is recurring, and may adversely affect the merchandise and consumer, CAPA for this problem is critical. The report is likewise developed defining needed corrective and preventive actions.

CAPA often entails problems spanning numerous features or departments. To guarantee that every one viewpoints are viewed as through the CAPA system, it is very important to require cross-useful teams.

Alterations shall be dealt with by read more closing the CAPA with correct justification, which include QA acceptance and opening a fresh CAPA by using a cross reference into the shut CAPA.

Powerful CAPA procedures are vital drivers for making high quality items. Prospects today can certainly observe a product’s authenticity and validity to safeguard by themselves from the minimal-top quality product or service.

Inside of a nutshell, both corrective action and preventive action are classified as the facets of the standard management method implemented in the Group.

Corrective action would be the one which handles nonconformity that has taken place. It requires under consideration the critical nonconformity which possesses a specific diploma of risk that demands an action to check here steer clear of the repetition of the danger and which ought to be recorded.

The corrective actions are promptly required to resolve the problems in the method. It can make confident that the process returns to standard Doing work parameters. Corrective actions will often be executed ahead of the Root Bring about Investigation stage.

One of many major advantages of CAPA is Price-conserving, leading to effective output with the best possible excellent. It boosts the reliability of processes, units, and products and solutions, Value personal savings, and better revenues that can be invested for even more advancements inside a virtuous expansion cycle.

A post-execution evaluation of CAPAs to confirm that carried out actions have the specified end result, as outlined because of the achievement standards.

Monitoring and Assessment - Constantly keep track of and evaluation the effectiveness of preventive actions executed. Frequent evaluations be certain that the preventive actions are effective in blocking comparable difficulties.

Jenna Von Oy Then & Now!

Jenna Von Oy Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Batista Then & Now!

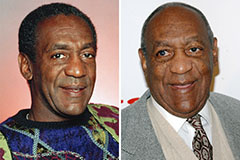

Batista Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!